Steel Guard Nano Coat (SGNC)

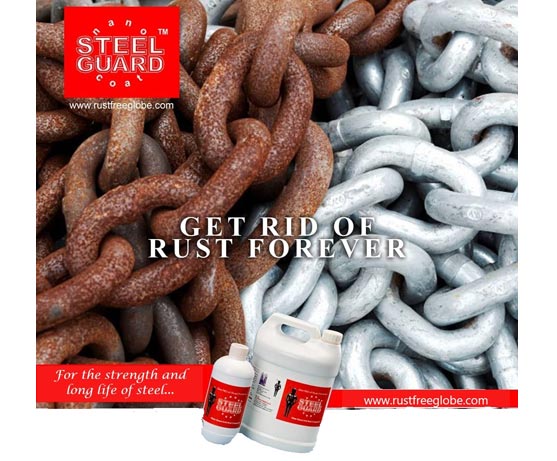

A very effective solution for permanent rust prevention in mild steel

Description

SGNC is the Inorganic Nano technological Water based chemical which has got the Vital properties as

- Permanent prevention from Corrosion (Rust)

- Mild Steel nobility enhancer

- Mild Steel& Paint adhesion booster

Areas of Application

Any kind of Mild Steel(MS) surface which needs painting on the top. E.G:

- Automobile Industry

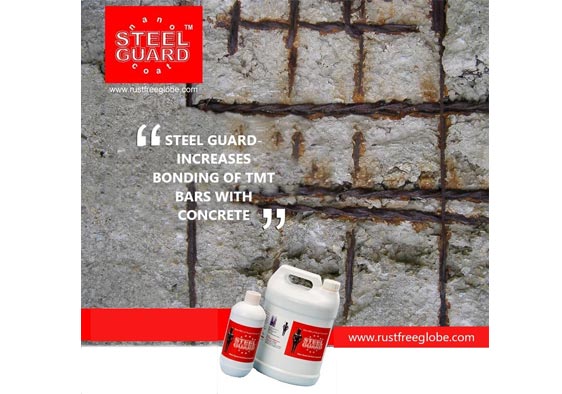

- Construction Industry

- Fabrication Industry

- Powder Coating Industry

- House Hold Applications

- Canopies

- Cranes

- Bridges

- Railway Rails, Sleepers

- Underground Pipelines

- Chemical plants structures

- Storage Tanks

- Petroleum Tanks

- Marine Applications

- Refineries’ Pipelines

- Agro Equipment

- Earth moving equipment

- Conveyor Structure

- Electrical poles

- Maintenance Components

- Hardware

Features

- Water Based Formulation

- Non Flammable

- Eco Friendly & pollution free

- Non Toxic

- Complies ROHS standard

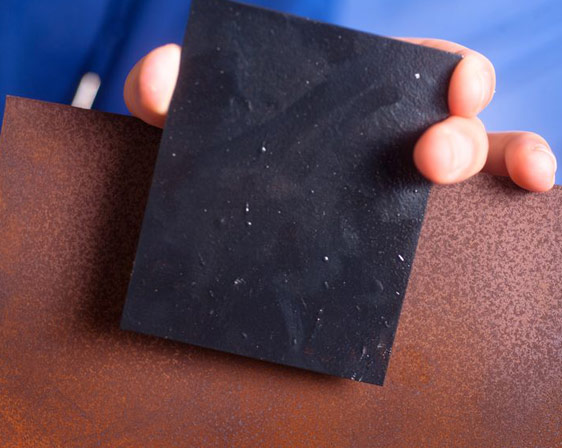

- No change in gauge of substrate after application.

- Easy to use; Spray, Dip or Brush application

- Stability to wide range of temperature

- Nano Coated steel can be painted, powder coated after application.

- Very good weld ability after drying

- Increases Adhesion with upper coats

- Maintains or improves the gloss level of the painted, powder coated surface.

- Stops ingress of water, oxygen and chloride.

- Increases Nobility of the MS to in between Silver and Gold.

Benefits

- Exceptional bonding properties increases the life of MS

- Easy to use, no special tools required

- Economical solution and cost reduction

- Environmentally safe. No pollution

- Mild rust present on the surface is converted in Nano composites and adheres to upper coats.

- Increase in gloss

- Reduces the maintenance cost

- SGNC becomes inseparable part of the base substrate

- Stops ingress of water oxygen and chloride.

- Fights against atmospheric pollution (Cosmetic & Corrosion)

- Compatible with all kind of primer and paints (Alkyd, Enamel, Epoxy, PU, Thermal plastic &Thermalsetting)

- Can avoid expensive processes like, Galvanizing, Plating, Shot blasting, Phosphating& electrodeposition.

Degrezzo –Dr 201

Powerful Decreasing Agent

Cleaning and decreasing treatments are one of the most crucial factors in fabrication and coating industry. Effective decreasing of components directly affects important parameters like corrosion resistance, topcoat and primer adhesion and overall performance of the end product.

Considering condition of metal, presence of grease, oils and soils and end use of the product on the field, use of Degrezzo -DR201 as decreasing agent can be the best option for better function of coatings done on the product.

Formulated by Altron Chemicals, Degrezzo – DR 201 is a powerful cleaner designed to remove a wide range of soils including oils, grease and grime from MS sheets, vehicle bodies as well as chassis.

Benefits of Degrezzo DR- 201

- Removes oil, grease and dirt

- Ideal for cleaning surfaces before applying any type of coating to vessels, chassis and components to be coated

- Effective formula ensures rapid penetration of stubborn deposits at economical dilution rates

- Contains water softeners and soil suspenders to remain effective even in areas with hard water

- Suitable for manual as well as pressure washer application

- Can be used to clean the grease, mud and crude from tools and equipment