Interlocking Devices

Enterprising Engineers (EE) is a leading manufacturer of high quality Interlocking Devices that comes with fail proof safety to assure consecutive operation of one or more equipment and are designed to solve the various challenging needs of this diversified market.

A vast range of Interlocking Devices by EE comes with the following amazing features:

- User Friendly Smooth Operation Device

- Precise and Positive Interlocking

- Visible Interlocked Condition in Casual Inspection

- Assured Appropriate Sequence

- Undefeatable Capability

- Robust Construction

Several types of Interlocking devices are – Key Exchange Box (Outside Control Lock with several Front Locks), Door Lock Type DT1 and DT2 and Mechanical Interlock Type DL

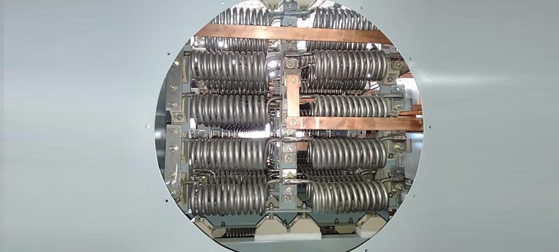

Liquid Resistance Starter

These are used for inserting external resistance in the rotor -circuit of slip ring induction motor at the starting to reduce starting – current and increase starting – torque used in various industries and installations like cement plants, rolling mills, pumping plants, sugar mills, paper plants.

EE manufacture and supply liquid rotor resistances with both motor operated or manually operated mechanism. These give step – less cutting of resistance and are economical in comparison to wire wound or grid resistances.

Buffer Resistance Panel

Buffer Resistance panel will be made-out by 2mm thick CRCA MS sheet steel, free standing, floor mounting, dust &vermin proof construction, indoor type, external & internal surfaces cleaned by chemical treatment, duly painted with approved paint shade. The Buffer Resistance panel having a set of Punched SS grid resistance cont. rated for the RA of the motor with a max. temp rise of 375 to 400oC and having an adequate ohmic value/ phase to run the slip ring motor at 15% slip regulation/regulator.

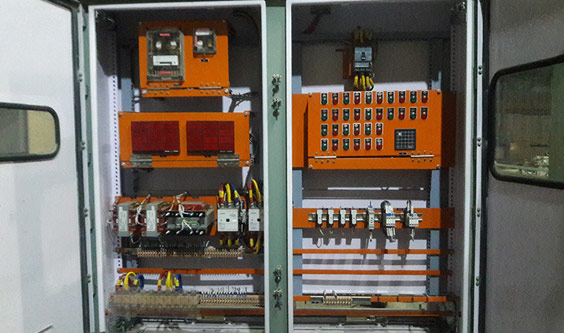

Grid Rotor Resistance Speed Regulator

It will have two units, free standing, floor mounting type made out of heavy gauge MS sheet & painted with Primer and two coats of anti-corrosive paint.

First unit will have two compartments – Contactor Panel and Resistance Box. The Contactor Panel will be dust & vermin proof and will house required Power Contactors to switch ON &OFF the Resistance Banks to attain required speed. The Resistance Box will be well Ventilated type & will house Resistance Banks.

Second Unit will be Control Panel/Speed Selector Panel free standing, floor mounting, dust & vermin proof. It will house the necessary control units like Aux. Contactors, Timers, Overload Relays, Indicating Lamps, Push Buttons etc. The Mini PLC used for setting of Logic controls of different speeds.

Grid Rotor Starter Panel (For Starting Duty)

Grid Rotor Starter Panel (for starting duty) will be made-out/fabricated by 2mm thick. CRCA MS sheet steel, dust &vermin proof construction, front operated, self-supported, free standing, floor mounting type, external & internal surfaces cleaned by chemical treatment, duly spray painted with approved paint shade.